Mineralogically identical to natural gypsum, FGD gypsum, or synthetic gypsum, is produced from gas captured within emission control systems at coal fired electric utilities.

An emission that would compromise air quality, sulfur dioxide (SO2) gas, is the primary contribution coal makes to FGD gypsum. Utilities that produce panel-grade synthetic gypsum beneficially reuse FGD sludge rather than landfilling the material.

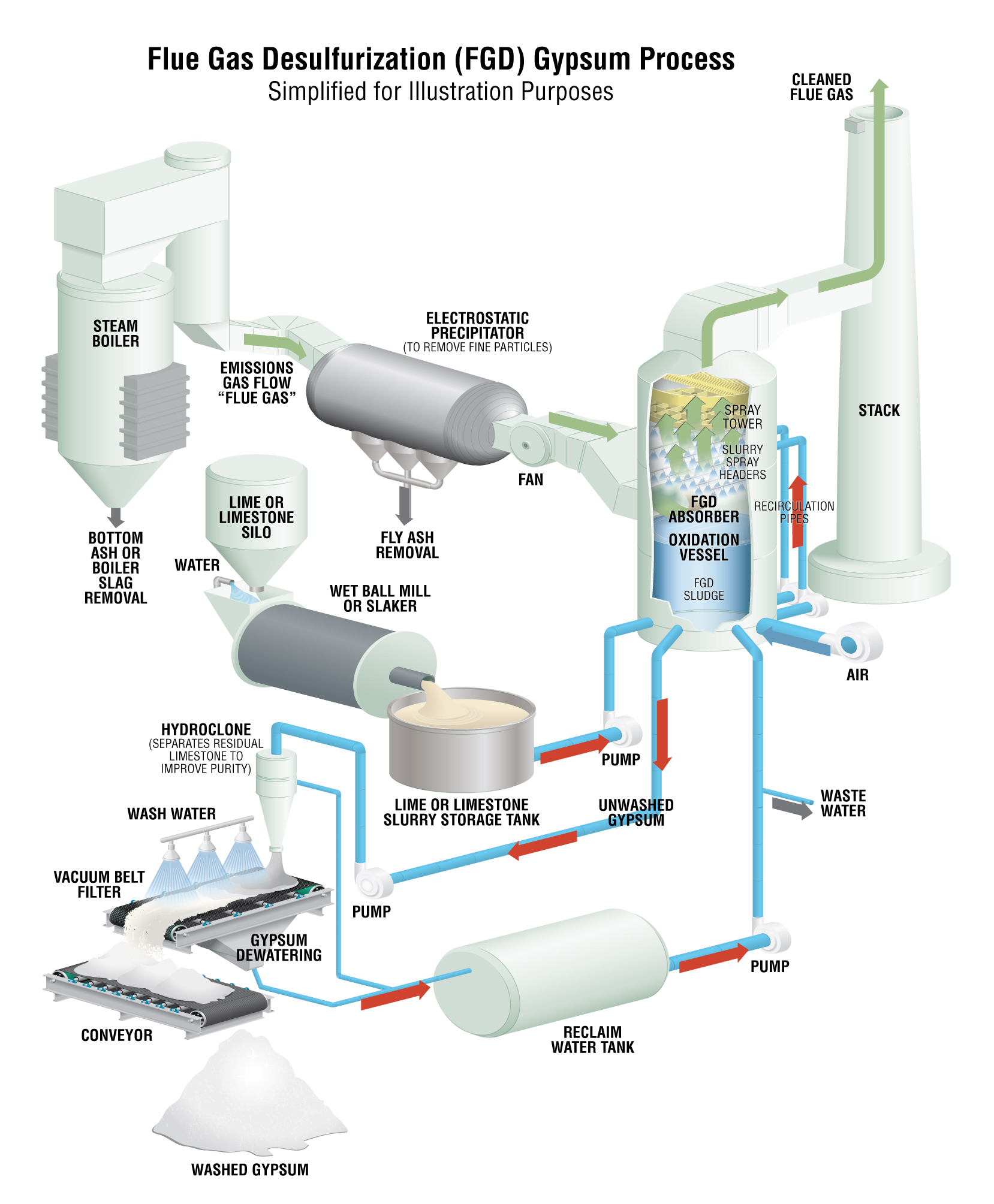

A multistage production process is necessary to transform the SO2 in flue gas, into panel-grade FGD gypsum that will meet the precise specifications of gypsum panel manufacturers. As flue gas is generated, it is passed through an electrostatic precipitator that separates fine particles, including fly ash, from the gas.

Next, a fan passes the flue gas into the absorber oxidation vessel. Inside, the gas is exposed to a water-based solution that contains fine-ground lime or limestone particulate. Scrubbing the sulfur dioxide from the flue gas by reaction with the lime or limestone produces calcium sulfite (CaSO3) sludge also referred to as FGD sludge. The cleaned flue gas is released into the air, while the sludge material is further refined for use in gypsum panels.

To make FGD gypsum, the sludge is oxidized by forcing clean, compressed air through it. In the oxidation vessel, calcium sulfite sludge is converted to calcium sulfate (CaSO4), which almost immediately combines with some of the water in the slurry to form calcium sulfate dihydrate (CaSO4·2H2O). The resulting slurry is often referred to as “unwashed” FGD gypsum.

The unwashed gypsum is further refined by concentrating the gypsum crystals and separating them from residual limestone in hydroclones to optimize purity. The hydroclone underflow, which contains the concentrated gypsum stream, is delivered to the belt filter for dewatering and washing.

Finally, the gypsum is “washed” using a vacuum filtering system to remove chlorides and salts and additional surface moisture. The removal of these impurities creates a high-quality gypsum that is suitable for use in manufacturing gypsum panels. This final step is critical to the production of panel-grade FGD gypsum. The dried, high-quality, panel-grade FGD gypsum or “washed gypsum” is transported to a manufacturing facility and becomes the primary ingredient in gypsum panels.