Fasteners and Adhesives (Preview)

Gypsum panels are typically installed to framing members using fasteners, or a combination of fasteners and adhesive.

Fasteners are defined as nails, screws, or staples used for mechanical application of gypsum panel products. While a variety of fasteners may be used to attach gypsum panels, all fasteners must be manufactured to specific minimum criteria to perform effectively.

Nails used to install gypsum panel products must be manufactured to comply with ASTM C514, Standard Specification for Nails for Application of Gypsum Wallboard. Nails manufactured to the standard are required to have a head not less than 0.2375 inches and not more than 0.3875 inches in diameter. Use of a nail with a smaller diameter head— such as a standard finishing nail— may not provide adequate fastening resistance for the panels. Use of a nail with a significantly larger head may lead to an unacceptable finished surface.

Nails should be driven so that nail heads are slightly below the surface of the face paper of the gypsum panel without breaking the face paper or fracturing the core of the board.

Screws used to install gypsum panel products to framing members must be manufactured to comply with ASTM C1002, Standard Specification for Steel Drill Screws for the Application of Gypsum Board. If the panels are being installed to heavy gauge metal framing members—with a metal thickness of 0.033 inch to 0.122 inch—then a screw complying with ASTM C954 should be used. Screws complying with ASTM C954 are commonly referred to as S-12 screws. C954 screws have a courser thread pattern than C1002 screws.

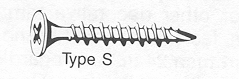

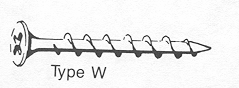

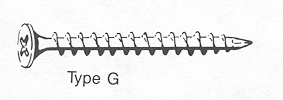

Screws manufactured to ASTM C 1002 are of three types:

Type S, shown above, for attachment of panels to steel framing.

Type W, shown above, for attachment of panels to wood framing.

Type G, above, commonly referred to as laminating screws, for attaching gypsum panel products to gypsum panel products.

A Type S screw may be used to attach panels to wood framing; however, the use of a Type W screw to attach panels to steel framing is not recommended. Compare the screw types above noting the differences in screw threads and patterns; especially the difference between Type S and the Type W screws.

The Gypsum Association recommends 30 mil (minimum 0.0296” base metal thickness) steel studs for use with abuse-resistant and impact-resistant (AR/IR) gypsum panels to minimize the occurrence of screw spin out. However, if the choice is made to install AR/IR panels on 20 EQ studs, with measured minimum thicknesses of 0.019”, then sharp point fine thread or sharp point high-low thread screws shall be used and the screw gun speed reduced to 2500 RPM. The use of drill point screws on 20 EQ studs is not recommended.

Screws should be driven so that screw heads are slightly below the gypsum panel surface without breaking the face paper, fracturing the core of the panel, or stripping the framing member around the screw shank as shown, below.

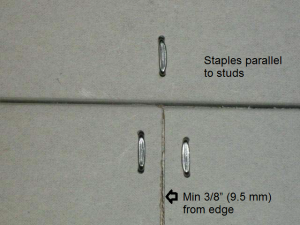

In specific situations, gypsum panel products can be attached with staples. Staples used to attach panels shall be 16 gauge, with not less than a 7/16 inch (11 mm) wide crown outside measure and should be driven with crowns parallel to framing members. The staple should not fracture the core and the head of the staple should not cut the face paper. See example, below.

When driving fasteners, gypsum panels should be held in firm contact with framing members or underlying support surfaces. Fasteners should be applied beginning in the center or field of the panel and proceed toward the ends and edges, or should begin along one edge and proceed sequentially toward the other edge.

Fasteners installed at panel edges and ends should be located at least 3/8 of an inch (9.5 mm) from the edge or end. In a perpendicular application fasteners should be located not more than 1 inch from the edge and end. It is not necessary—and it is not recommended—to install fasteners in partition top and bottom sole plates except where fire ratings, structural performance requirements, or other special conditions require attachment.

Adhesive application of gypsum panel products to wood framing members is permitted under the following conditions:

- Panels and framing surfaces should be dry and free from dirt, dust, grease, or other foreign matter that impairs bonding.

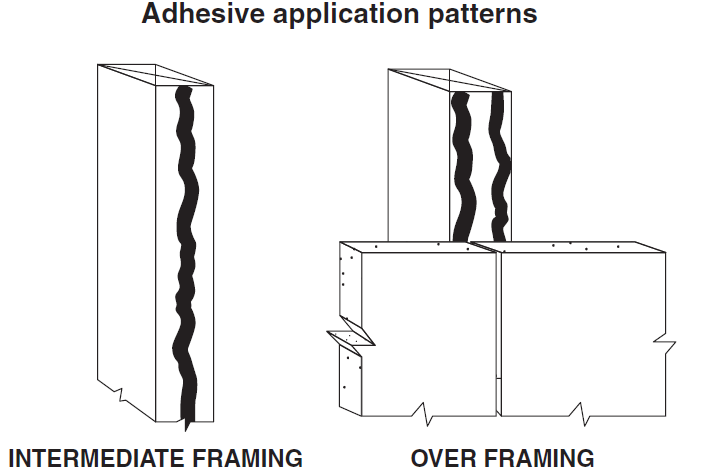

- A bead of adhesive not less than 3/8 in. (10 mm) in diameter should be applied to the face of all framing members except top and bottom (sole) plates, that are to support the gypsum panel product (see illustration, below.) When the gypsum panel is placed, the adhesive should spread to an average width of 3/4 in. (19 mm) and approximately 1/16 in. (1.5 mm) think.

- At edge or end joints, two parallel beads of adhesive not less than 3/8 in. (10 mm) in diameter shall be applied, one near each edge of the framing member.

- On ceilings, temporary field nailing or bracing may be necessary until the adhesive bond develops. Consult the manufacturer of the gypsum panel product or the adhesive for additional guidance.

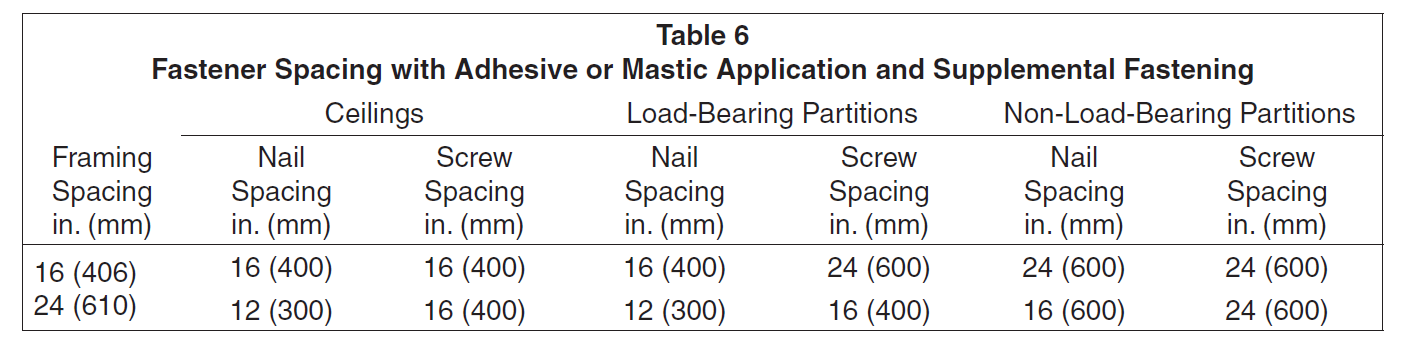

Unless otherwise specified by either the gypsum panel manufacturer or the adhesive manufacturer, Table 6 in GA-216-2021 should guide fastener spacing when using adhesive or mastic.