Gypsum Shaftliner Panels: Commercial Construction

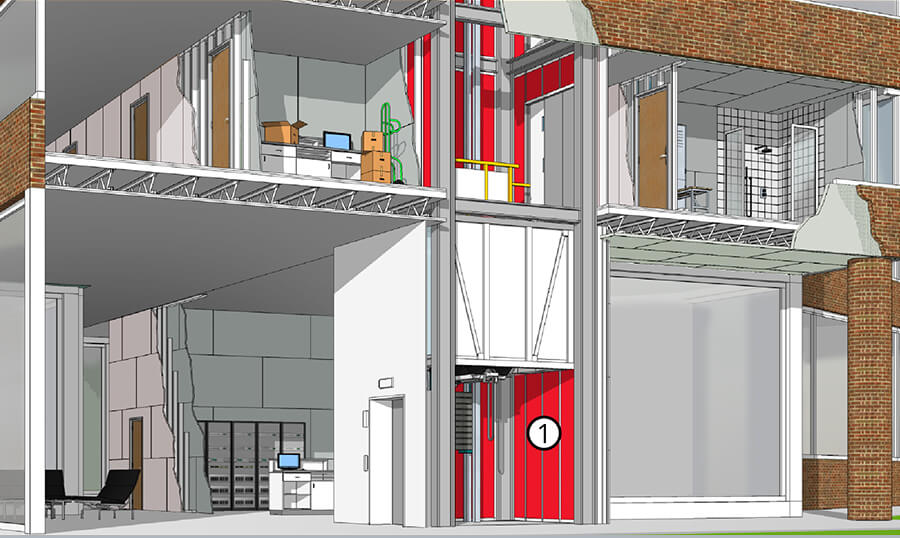

Providing an efficient shaft wall construction alternative to masonry

Gypsum Shaftliner Panels create shaftwall systems that are easy to build and highly resistant to fire.

Physical Description

Gypsum Shaftliner Panels are special performance panels manufactured with a thick, noncombustible Type X core wrapped in either heavy-duty paper facers or sturdy fiberglass mats. Most shaftliner panels also feature enhanced mold and moisture resistance as a standard product property and beveled edges on the long dimension to aid with installation in metal framing. Gypsum Shaftliner Panels are produced 1” (25.4 mm) thick by 24” (610 mm) wide and 8’ (2440 mm) to 12’ (3660 mm) in length. The applicable product manufacturing standard is ASTM C1396 and ASTM C1658.

Advantages and Benefits

The development of Gypsum Shaftliner Panels dramatically changed the way access and mechanical shafts and area separations walls could be designed and constructed in a commercial structure. Here are several advantages this product has to offer your next project:

o Fire Resistance – Shaft walls and area separation walls constructed with Gypsum Shaftliner Panels are capable of achieving a range of levels of fire protection to meet the design requirements of different structures and applications. These 1”-thick, noncombustible Type X panels are UL-classified for use in vertical wall assemblies designed to provide fire-rated values of 1, 2, 3 and even 4 hours. Their tested flame-spread and smoke-developed surface burning characteristics are also extremely low. Refer to GA-600 Fire Resistance and Sound Control Design Manual.

o Construction Efficiency – Gypsum Shaftliner Panels make it possible to build multi-floor shaft wall and area separation wall systems in a commercial structure without the time, weight and cost burdens of masonry construction. That’s because the assembly of lightweight metal framing is fast and reliable using tools and craftsmen already building other partition structures onsite. Plus, shaftliner panels are available to quickly span the typical height between floors, fit tightly into multiple metal framing systems and allow size adjustments and cutouts to be made easily with a saw or knife. In addition, shaft walls built with these panels can be constructed from outside the shaft itself, eliminating the need for increasingly taller scaffolding and its procurement, storage and assembly.

o Wall Strength – Engineered to handle the stresses, wind pressures and vibrations created by the rapid movement of modern elevator carriages, Gypsum Shaftliner Panels can be a strong, durable component of a structure’s access and mechanical shafts as well as area separation fire walls.

o Mold and Moisture Resistance – In the same way Gypsum Shaftliner Panels help protect a building’s access and mechanical shafts from flame spread, they can also help resist the development and spread of mold and mildew. Both the core and facers of many brands of shaftliner panels are manufactured with moisture-resistant, anti-microbial properties. Consult the manufacturer for specific test results and recommendations.

o Sound Control – Wall assemblies built with Gypsum Shaftliner Panels can be very effective barriers to the transfer of sound vibrations from one space to the adjoining areas within a structure. This is especially valuable when trying to buffer a building’s occupants from equipment noise including hotel rooms adjacent to an elevator or mechanical shaft. In other cases, Gypsum Shaftliner Panels contribute to excellent separation walls to shield tenants from the unwanted noise of their neighbors in residential or office settings. more

Limitations

To deliver the expected shaftwall or firewall performance defined in a project’s design requirements, a number of basic limitations should be followed. These recommendations are intended to provide general information only about considerations that are common in this category of special performance gypsum products:

o intended for interior use only

o not designed for use in a load-bearing capacity

o not intended for constant exposure to moisture, ponding or cascading water

o avoid exposure to prolonged temperatures exceeding 125°

o maximum height and deflection limits should be based on metal framing manufacturer’s recommendations

o not intended for use as an unlined air supply duct

o board should be stored flat, off the ground, and kept dry prior to installation

Refer to GA-216 Application And Finishing Of Gypsum Panel Products for specific guidelines related to the application and finishing of gypsum panel products.

Products vary by brand. For more specific limitations related to the gypsum panel you are considering, consult with the product’s manufacturer.

Frequently Asked Questions

Below are answers to typical questions our technical experts address on a routine basis. These answers may provide additional information you are seeking as well. To submit an inquiry of your own, click here.

1. Aside from elevator shafts and stairwells, are there other applications for shaftliner? What are some considerations for those applications?

Fire-rated assemblies using shaftliner board can be substituted, within the bounds of the design and code, in many other vertical fire-rated wall and partition applications. Additionally, shafts do not just include elevators, but mechanical raceways and service shafts such as those for laundry or rubbish. In the case of the latter, verify local code acceptability and be aware that these boards can have “rough” surfaces that may slow or stop laundry and rubbish, causing clogs. Lining with sheet metal or other smoother material may be called for by the designer or code official.

For Further Information

To read more about the testing procedures to evaluate the moisture-resistant characteristics of the core and facers of a gypsum panel product, refer to ASTM C473.

To read more about the testing procedures to evaluate the mold-resistant properties of the core and facers of a gypsum panel product, refer to ASTM D6329.