Panel Installation and Joints Between Panels (Preview)

Panels should be installed so that they are in contact with each other;  however, they should not be forced together. Ends and edges of panels should be smoothed as necessary to obtain neat fitting joints and to permit panels to rest flat against framing members. Panels and framing members should be clean and free of dirt and other contaminants that would prohibit a tight fit and panels should be securely fastened to framing members.

however, they should not be forced together. Ends and edges of panels should be smoothed as necessary to obtain neat fitting joints and to permit panels to rest flat against framing members. Panels and framing members should be clean and free of dirt and other contaminants that would prohibit a tight fit and panels should be securely fastened to framing members.

Ends and edges of panels should be located over framing members or other solid backing, except as follows:

- Panel joints that are oriented at right angles to wall or ceiling framing members.

- Panel ends and edges that are oriented at right angles to wall framing that occur above ceilings when the panels are terminated at less than full height of the framing.

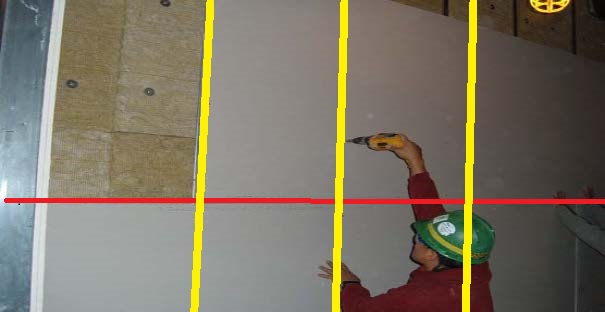

In the photo below, note that the panel edges identified by the red line are not backed by a framing member nor are they supported by supplemental backing material. This is acceptable since the panel edge is oriented at a right angle to the framing members indicated by the yellow lines.

Note that the exceptions for backing of joints may be superseded by the requirements of a fire- or sound-test, or by the use of a panel in a system that is designed to perform a specific structural function such as a shear wall system or diaphragm ceiling.

Model code requirements for the application of panels in systems that are constructed to be fire- or sound resistant typically require systems to exhibit compliance with the concept of “moderate contact” for panel edges. Moderate contact means that panel edges are essentially touching each other. It is possible for the panel edges to be in moderate contact yet not touch along the entire length of the panels. Therefore, in panel systems rated for fire, sound, or shear, small gaps spaced sporadically along the joint are acceptable as long as the panel edges are essentially touching each other.

For applications where panels are not part of a rated system, good construction practices dictate that moderate contact should continue to be the goal for joint tolerance.

Gaps between panels in any system should not be greater than ¼ inch (6 mm). Gaps less than 1/8 inch (3 mm) in width should be prefilled with either ready-mix or setting-type joint compound. Gaps greater than 1/8 inch (3 mm) in width should be prefilled with setting-type compound.