Spacing and Installation of Fasteners (Preview)

Similar to the requirements for spacing of framing members, the requirements for spacing of the fasteners used for a gypsum panel installation are a function of variable factors. These include:

- Type of fastener;

- Number of layer of panels;

- Type of framing member;

- Use of fastening adhesive; and

- Orientation of the framing system (wall or ceiling).

Requirements for fastener spacing with wood framing members can be found in section 5 “Application of Single Layer Gypsum Panel Products to Wood Framing Members.”

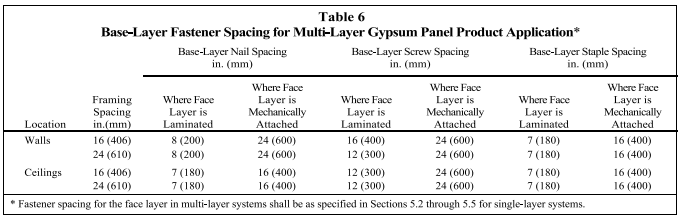

Base layers in multi-layer wood-frame systems should be installed in accordance with Table 6 of GA-216, as shown below. Face layers in wood-frame systems are installed in accordance with Section 6, “Application of Multi-Layer Gypsum Panel Products to Wood Framing Members.”of GA-216. Face layers in systems installed with adhesive between layers are installed in accordance with Section 7 “Adhesive Application of Gypsum Panel Products to Wood Framing Members.”of GA-216.

Requirements for fastener spacing using steel framing members in a variety of scenarios are summarized in Section 8, “Gypsum Panel Product Application over Steel Framing and Furring.”

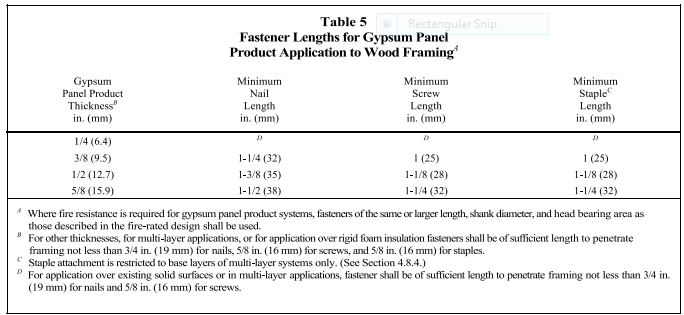

The length of fasteners used to attach gypsum panels to framing members is important. Use of excessively long fasteners, particularly nails, is discouraged. In general, nails used to attach panels to wood framing should penetrate into framing members at least 7/8-inch on a single layer application and ¾-inch for a multi-layer application. Screws and staples should penetrate at least 5/8-inch. Specific requirements are contained in Table 5 of GA- 216.

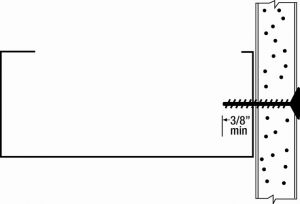

Screws used to attach panels to steel framing and furring must penetrate into framing members at least 3/8-inch.