Exterior Gypsum Sheathing: Single-Family Homes

Weather-resistant panels are a stable foundation for many exterior finishes

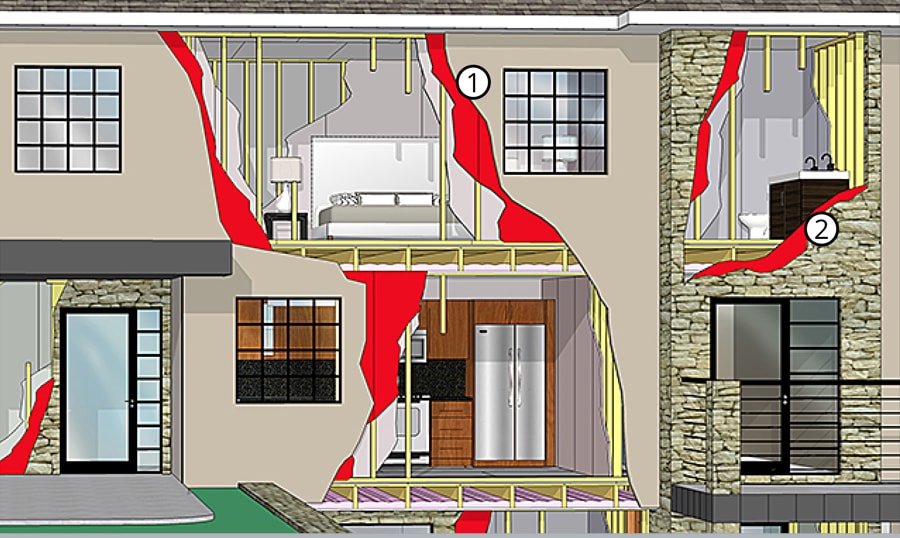

Glass Mat Gypsum Sheathing helps exterior walls resist air, water and noise infiltration.

Physical Description

Exterior Gypsum Sheathing is a special-purpose drywall panel consisting of a moisture-resistant, noncombustible core covered by glass-mat facers on both front and back surfaces and long edges. It is manufactured with square edges in both 1/2” (12.7 mm) and 5/8” (15.9 mm) thicknesses, a 48” (1.2 m) width and lengths from 8’ (2.4 m) to 16’ (4.9 m). Typically, 1/2” (12.7 mm) panels feature a regular core and 5/8” (15.9 mm) panels are produced with a Type X core for use in fire-resistive assemblies. The applicable product manufacturing standard is ASTM C1177. Refer to GA-254 Fire-Resistant Gypsum Sheathing.

Advantages and Benefits

Gypsum Sheathing is well established as a cost-efficient exterior substrate in commercial construction. Its popularity is growing in single-family construction as more architects and builders discover these important performance advantages.

o Weather Protection – Manufactured with improved moisture-resistance in mind, Gypsum Sheathing’s specially treated core and glass mat facers help provide a water and air infiltration barrier when applied as a component of a home’s exterior wall assembly. Additionally, these same features help protect the product itself during construction when periodic weather exposure can occur prior to complete envelope enclosure.

o Mold Resistance – Mold resistance starts with moisture resistance. Exterior Gypsum Sheathing’s glass mat facers are naturally mold and moisture resistant. Its core is often specially formulated with water-repellant and anti-microbial additives. The result is a material that performs extremely well in laboratory mold tests conducted in accordance with ASTM D3273. Just as important, however, Gypsum Sheathing still maintains permeability to allow water vapor originating inside the structure to escape before it becomes a bigger issue.

o Fire Resistance – With fire safety becoming an increasingly important homeowner sales benefit, especially in natural or woodland settings, Gypsum Sheathing has a lot to offer. It’s produced in a 5/8” (15.9 mm) thickness and features a UL-classified, Type X core. These noncombustible panels have been fire-tested and approved for use in multiple fire-rated assemblies. In addition, they also produced extremely low flame spread and smoke-generated values when evaluated per ASTM-E84 Standard Test Method for Surface Burning Characteristics of Building Materials. Refer to GA-600 Fire Resistance and Sound Control Design Manual.

o Exterior Systems Compatibility – Many different types of exterior cladding systems can be very successfully installed over exterior Gypsum Sheathing. This includes wood, brick, stone, metal and vinyl, as well as popular EIFS and stucco systems. Weather-resistive barriers and coatings also work well with Gypsum Sheathing as a substrate.

o Construction Efficiency – Easy to cut and fasten, Gypsum Sheathing does not require power tools to install so it’s very time and labor efficient. Suitable for both vertical walls and overhangs under many different finishes, Gypsum Sheathing also contributes to more efficient material purchasing and storage management.

o Noise Attenuation – Enhanced sound control is another increasing expectation in single-family construction. Gypsum Sheathing is a component material in a number of sound control assemblies developed to dissipate the energy of sound moving within and through a structure’s walls. more

Limitations

To fully meet the design objectives required for a structure’s exterior wall and ceiling surfaces, a number of important limitations should be followed to maximize the performance of Glass Mat Gypsum Sheathing. These recommendations are intended to provide general information only about considerations that are common in this category of special performance gypsum products:

o Gypsum Sheathing is not designed to be a nail base for exterior cladding – fasteners must be attached to furring strips or framing

o maximum framing spacing should be no greater than 24” (610 mm) o.c., as dictated by the code

o do not apply panels below grade

o do not laminate Gypsum Sheathing directly to masonry surfaces – use furring strips or framing

o not intended for use as an interior or exterior tile backer

o not designed to replace structurally engineered sheathing in shear walls

Refer to the document GA-253 Application of Gypsum Sheathing for specific guidelines related to the handling and application of exterior Gypsum Sheathing.

Products vary by brand. For more specific limitations related to the gypsum panel you are considering, consult with the product’s manufacturer.

Frequently Asked Questions

Below are answers to typical questions our technical experts address on a routine basis. These answers may provide additional information you are seeking as well. To submit an inquiry of your own, click here.

1. How long can exterior Gypsum Sheathing be exposed to the elements?

Exterior Gypsum Sheathing should never be stored outside while awaiting application. Details on the safe handling and storage of all gypsum panel products is available in the free technical document GA-801 Handling and Storage of Gypsum Panel Products.

Prevailing weather conditions will dictate how long exterior Gypsum Sheathing can be exposed to the elements after installation. Weather exposure of up to one month should not affect performance. Contact the manufacturer if you have questions related to a specific job or set of weather-related conditions as extended exposure recommendations vary by product brand.

2. How is Gypsum Sheathing cut and installed?

Detailed instructions for the application of Gypsum Sheathing are provided in the Gypsum Association’s free technical document GA-253 Application of Gypsum Sheathing. Gypsum Sheathing is easily cut to size with a utility knife. No special tools are required. Joints between sheathing panels should be staggered. Sheathing is nailed, screwed, or stapled directly into wood or steel framing in such a manner that the fastener sits tightly against the sheathing without breaking the glass mat surface. GA-253 provides essential information on the type and size of fasteners, the appropriate water-resistive barriers for application to installed sheathing, as well as details on cutting holes for pipes and other utilities and the application of flexible water-resistant sealant to those openings.

3. Does Gypsum Sheathing offer any advantages to a builder of single-family homes?

When compared to wood sheathing alternatives, exterior Gypsum Sheathing has greater fire resistance and mold and moisture resistance. Because it contains no wood, glass mat Gypsum Sheathing is not susceptible to attack by wood boring insects. Easier to install and repair than wood products, Gypsum Sheathing is not a nail base for fasteners but is an excellent substrate for stucco, EIFS, stone and brick, as well as wood and composite siding products and more. While Gypsum Sheathing does not provide racking quality, this limitation is easily overcome through the addition of bracing.