Impact-Resistant Gypsum Panels: Single-Family Homes

A smart strategy to resist impact damage and reduce maintenance

Impact-Resistant Gypsum Panels enhance wall surface and core toughness to reduce potential damage.

Physical Description

Impact-Resistant Gypsum Panels are made by combining a high-density Type X core with either extra-durable paper or fiberglass facers, plus an additional fiberglass reinforcing mesh layer. The result is a product offering enhanced resistance to both surface damage and wall cavity penetration. Panels are typically 5/8” (15.9 mm) thick, 48” (1.2 m) wide and 8’ (2.4 m) to 12’ (3.7 m) long. Long edges are generally tapered to make joint finishing easier and wrapped with the board’s facer material. Short edges are trimmed square. If paper facers are applied, 100% recycled fiber content can provide valuable contributions to help achieve environmental objectives. The applicable product manufacturing standard is ASTM C1629.

Advantages and Benefits

Impact-Resistant Gypsum Panels are an excellent home design solution to help minimize wall damage in high-risk locations from occupant or hard object contact, but they can also contribute other valuable benefits as well.

o Construction Efficiency – Impact-Resistant Gypsum Panels are installed with the same time-efficiency and construction process as standard drywall panels but create a wall with significantly better resistance to surface indentation and even penetration. This material choice also makes remodeling and reconfiguring at a later date an easier process because of its common cutting, fastening and finishing procedure.

o Wall Performance – Laboratory testing provides a relative numeric value for comparing the level of protection Impact-Resistant Gypsum Panels provide against certain types of damaging conditions. Measurements consider surface wear and abrasions, minor indentations and both soft- and hard-body impacts.

o Maintenance Simplicity – Filling, patching and even replacing Impact-Resistant Gypsum Panels is fast, easy and cost efficient. Its durability is designed to make repairs less frequent, but, when necessary, the process and carpentry skills required are the same as any other gypsum drywall product.

o Mold and Moisture Protection – Most Impact-Resistant Gypsum Panels are now treated to add greater protection against moisture absorption and mold growth too. This not only increases the range of locations within a home where the product can be specified, but it can also contribute to a healthier living environment and lower maintenance costs.

o Fire Resistance – Manufactured with a non-combustible Type X core, 5/8” Impact-Resistant Gypsum Panels are UL Classified for use in many different fire-rated assemblies. Refer to GA-600 Fire Resistance and Sound Control Design Manual for more ideas of how to use this product anywhere a 5/8” Type X panel is approved.

o Noise Reduction – Impact-Resistant Gypsum Panels can be used in wall assemblies designed to minimize the transfer of sound waves within a home. Refer to GA-600 Fire Resistance and Sound Control Design Manual to select design options that can provide a range of tested sound attenuation performance. Consult with gypsum manufacturer for specific recommendations. more

o Finishing Flexibility – Impact-Resistant Gypsum Panels offer the same finishing and decorating flexibility as traditional drywall panels.

Damage-Resistance Classifications

To provide a way of comparing the expected performance of different brands of Impact-Resistant Gypsum Panels, laboratory tests are conducted in accordance to ASTM C1629 to simulate typical wear that might be experienced in a single-family structure application. Product samples are exposed to four different potentially damaging forces on specially designed test equipment and ranked into one of three different classifications based on the degree of damage each sample sustains.

o Surface Abrasion – Measures the ability of a gypsum panel’s facer to resist surface scratches and scuffs by exposing the panel to a 25 lb. weighted wire brush held against the sample’s surface while the sample is moved back and forth 50 times. Based on the depth of the abrasion at the conclusion of the test cycle, the board is assigned to one of three classification levels.

| Classification Level | Max. Abrasion Depth |

|---|---|

| 1 | 0.126″ (3.2mm) |

| 2 | 0.59″ (1.5mm) |

| 3 | 0.010″ (0.3mm) |

o Surface Indentation – Measures the ability of a gypsum panel to resist dents caused by small, hard objects by exposing the panel to the impact of a round-tipped rod. Based on the depth of the indentation the impact causes, the board is assigned to one of three classification levels.

| Classification Level | Max. Indentation Depth |

|---|---|

| 1 | 0.150″ (3.8mm) |

| 2 | 0.100″ (2.5mm) |

| 3 | 0.050″ (1.3mm) |

o Soft-Body Impact – Measures the ability of a gypsum panel to resist a single impact from a heavy soft object by exposing a sample panel to the impact of a swinging leather bag loaded with steel pellets. Based on the energy required to fracture the panel calculated from the leather bag’s weight and drop height, the board is assigned to one of three classification levels.

| Classification Level | Min. Fracture Energy |

|---|---|

| 1 | 90 ft·lbf (122 J) |

| 2 | 195 ft·lbf (265 J) |

| 3 | 300 ft·lbf (408 J) |

o Hard-Body Impact – Measures the ability of a gypsum panel to resist the impact of a hard object by exposing a sample panel to the impact of a steel cylinder on a pendulum. Based on the amount of force required for the cylinder to penetrate through the panel, the sample is assigned to one of three classification levels.

| Classification Level | Min. Penetration Energy |

|---|---|

| 1 | 50 ft·lbf (68 J) |

| 2 | 100 ft·lbf (136 J) |

| 3 | 150 ft·lbf (204 J) |

Gypsum panel performance characteristics vary by manufacturer. Consult with the gypsum manufacturer you are considering for the specific classification levels that pertain to your project goals.

Limitations

Impact-Resistant Gypsum Panels are designed to provide a number of valuable benefits both in the construction and in the maintenance of a single-family home when important limitations are observed. These recommendations are intended to provide general information only about considerations that are common in this category of special performance gypsum products:

o Impact-Resistant Gypsum Panels are intended for interior use only

o Impact-Resistant Gypsum Panels are nonstructural and are not designed to be a fastener base for mounting other materials

o maximum framing spacing should be no greater than 16” (406 mm) o.c.

o avoid exposure to prolonged temperatures exceeding 125°

o do not finish Impact-Resistant Gypsum Panels before structure is properly enclosed

o not intended for constant exposure to moisture, ponding or cascading water

Refer to the document GA-216 Application And Finishing Of Gypsum Panel Products for more specific information.

Products vary by brand. For more specific limitations related to the gypsum panel you are considering, consult with the product’s manufacturer.

Frequently Asked Questions

Below are answers to typical questions our technical experts address on a routine basis. These answers may provide additional information you are seeking as well. To submit an inquiry of your own, click here.

1. I’m a little confused. Where should I use abuse-resistant wallboard and where should I use impact-resistant wallboard?

Many designers find that either board will work fine in areas that are subject to a little more “wear and tear.” However, there are some differences to keep in mind when selecting the best board for your application. For example, boards classified as abuse resistant typically have higher abrasion and indentation resistance (meaning a classification level of 2 or 3 per ASTM C1629 for both). Boards that are impact resistant would have similar classification levels for the hard and soft body tests in C1629.

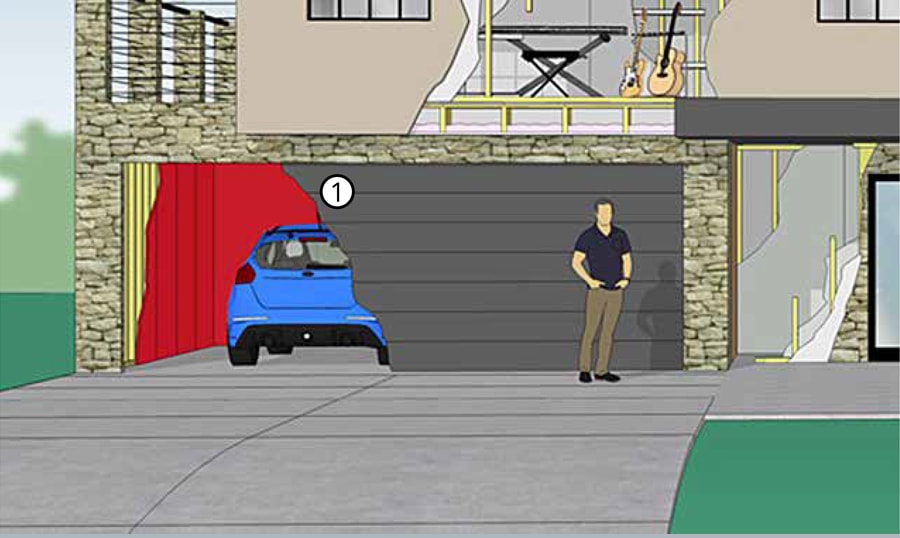

So, is it more likely that the wall could be regularly “side-swiped” by a child carrying sports equipment, or someone carelessly carrying a package? Or, is it more likely someone might hit the wall “full-on” with a large object as might happen in a home workshop or garage? If the answer is “side-swiped”, you should probably consider abuse-resistant boards. If the answer is “full-on,” then you may wish to choose impact resistant to reduce the likelihood of penetration into the wall cavity.

2. Does the additional panel strength of abuse- or impact-resistant panels allow them to be applied on assemblies with wider spacing?

No. Stud and frame spacing is dictated by design standards and the building code.